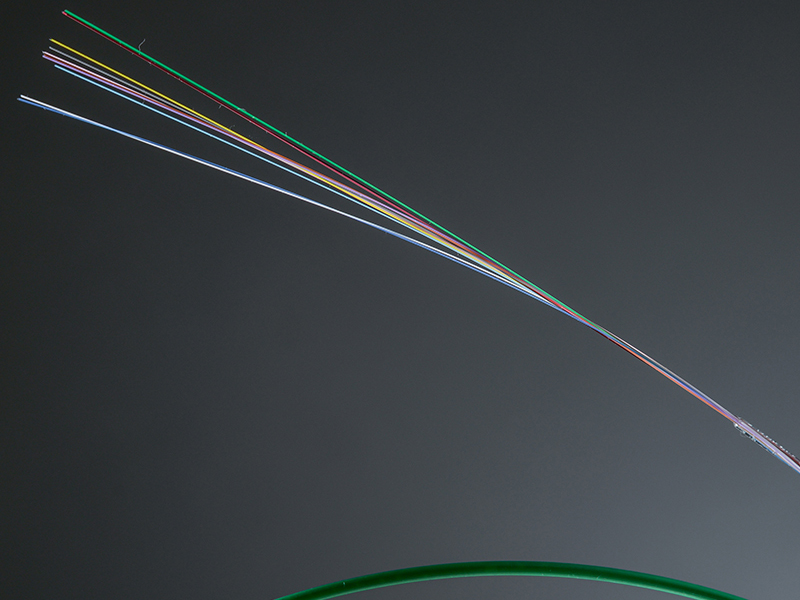

Super Mini FTTX 2~24 core OM2 Multi Mode Air Blown Fiber Optic Cable

Technical Specifications for Super Mini Uni-tube Air Blown Cable

(ITU-T OM2 Multi Mode Fibers)

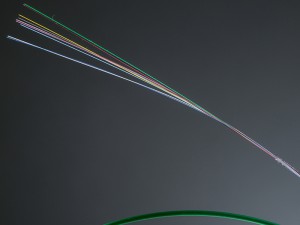

Air Blown Super Mini Cable (MINI) is small size, light weight, enhanced surface outer sheath fiber unit designed for blowing into micro tube bundles by air flow. The outer thermoplastic layer provides a high level of protection and excellent installation properties.

It is usually applied in FTTX.

Features and Benefits

* Special complex material loose tube, reduce the shrink of tube in cold temperature.

* Accurate fibre length balance, stable mechanical and temperature performance.

* Particular technique control, prevent sheath form crinkling during installation.

* Structure Innovation in sheath, enhancing the blowing performance.

* Small diameter

* Cost saving

* Network design flexibility

* 5/3.5mm microduct suitable

* Easy to upgrade

Standards

Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard.

Optical fibre …..ITU-T G652, G657, OM1, OM2, OM3, OM4; IEC 60793-2-50

Optical cable ….IEC 60794-5, IEC 60794-1-2

Technical Index

| Cable Type |

GYCFXY-XB1.3(MTE + Cable diameter) |

|||

|

MTE2.0 |

MTE2.3 |

MTE2.5 |

MTE2.8 |

|

| Fibre Count |

2~4 |

6~12 |

2~12 |

14~24 |

| Thickness of HDPE sheath |

Nominal value:0.20mm, Average value:0.15mm |

|||

| Nominal Overall Diameter |

2.0±0.1mm |

2.3±0.1mm |

2.5±0.1mm |

2.8±0.1mm |

| Weight |

4.0 kg/km |

5.0 kg/km |

6.0 kg/km |

7.0kg/km |

| Cable Fibre Attenuation |

0.35dB/km max @1310nm 0.22dB/km max @1550nm |

|||

| Max. Tensile Strength |

40N |

50N |

60N |

60N |

| Max. Crushing force |

600N/100mm |

|||

| Min. Bending radius -Static / Dynamic |

10 / 20 outer Φ |

|||

| Temperature |

Storage -30~+50℃;Installation-10~+40℃;Operation-20~+50℃ |

|||

| Cable service life (estimate value) |

25 years |

|||

Blowing Performance

|

Blowing Tool |

Typical blowing length |

||

| PLUMETTAZ:PR-140, MiniJet-400 etc.Air pressure : 13bar |

Fibres Count |

Duct type 3.5/5.0mm |

Duct type 5.5/7.0mm |

|

2~12 fibres |

800m |

1500m |

|

|

14~24 fibres |

/ |

1500 |

|

Mechanical Performance

|

Item |

Testing Method |

Testing Results |

Specified Value |

|

|

Tension performance |

IEC 60794-1-21-E1 |

Optical fibre strain |

Additional attenuation |

Max. Tensile Strength =Short term Allowable tension≈2×(Long term AllowableTension) |

|

Short term:≤0.3% Long term:≤0.1% |

Short term:<0.1 dB,Δα reversible;Long term:Δα ≤0.03 dB | |||

|

Crush |

IEC 60794-1-21-E3 |

Short term:Δα <0.10 dB, Δα reversible;Long term:Δα ≤0.03 dB;The outer sheath has no visible crack. | Short termcrushing force =600 NLong termcrushing force =300 N | |

|

Repeated bending |

IEC 60794-1-21-E6 |

After test, Δα ≤0.03 dB;The outer sheath has no visible crack. | R=20 outer Φ | |

| Bending load =15N | ||||

| Bending times =25 | ||||

|

Torsion |

IEC 60794-1-21-E7 |

After test, Δα ≤0.03 dB;The outer sheath has no visible crack. | Torsion angle=±180º | |

| Torsion load =15N | ||||

| Torsion times =5 | ||||

|

Cable bend |

IEC 60794-1-21-E11A |

After test, The optical fibre can’t be broken;The outer sheath has no visible crack. | R=20 outer Φ10TurnsCycles times =5 | |

|

All optical testing proceeded at 1550 nm |

||||

Environment performance

|

Item |

Testing Method |

Testing Results |

|

Temperature cycling |

IEC 60794-1-22-F1 |

Allowable additional attenuation (1550nm) |

|

G.652D |

||

|

≤0.10 dB/km, Δαreversible; |

||

|

Water penetration |

IEC 60794-1-22-F5B |

Water column:1m,3mcable, Period:24 hours No water leak through the open end of cable |

|

Filling compound flow |

IEC 60794-1-22-F16 |

70℃,Period:24 hours No compound flow from the cable |

Optical Fiber Characteristics

The optical, geometrical, mechanical and environment characteristics of the ITU-T OM2 optical fiber shall be accordance with below table:

| Characteristics | Specified Values | Units | |

| Optical Characteristics | |||

| Attenuation coefficient | at 850nm | ≤3.5 | dB/km |

| at 1300nm | ≤1.5 | dB/km | |

| Bandwidth (OFL) | @ 850nm | ≥800 | MHz.km |

| @ 1300nm | ≥500 | MHz.km | |

| Attenuation non-uniformity | ≤0.1 | dB | |

| Zero dispersion wavelength ( λ0) | 1320 ~1365 | nm | |

| Dispersion coefficient | @ 1295 ~ 1310nm | £ 0.11 | ps/(nm·km) |

| @ 1310-1340nm | £0.001(1458-l0) | ps/(nm·km) | |

| Effective group index of refraction (Neff) | at 850nm | 1.496 | - |

| at 1300nm | 1.491 | - | |

| Numerical aperture | 0.275± 0.015 | - | |

| Geometric characteristic | |||

| Core diameter | 62.5 ± 2.5 | µm | |

| Core non-circularity | ≤5.0 | % | |

| Cladding diameter | 125.0±1.0 | µm | |

| Cladding non-circularity | ≤1.0 | % | |

| Coating diameter | 245±10.0 | µm | |

| Coating-cladding concentricity error | ≤12.0 | µm | |

| Coating non-circularity | ≤6.0 | % | |

| Core-cladding concentricity error | ≤1.5 | µm | |

| Mechanical characteristic | |||

| Proof stress | ≥0.69 | GPa | |

| Coating strip force | Average value | 1.0-5.0 | N |

| Peak value | 1.3-8.9 | N | |

| Macro bending loss | Ф75mm, 100 circles, at850nm | ≤0.5 | dB |

| Ф75mm, 100 circles, at 1300nm | ≤0.5 | dB | |

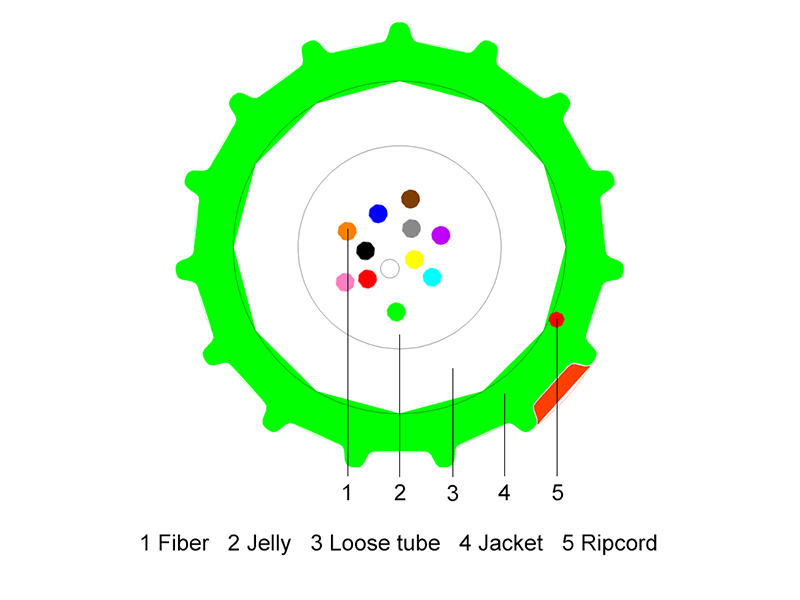

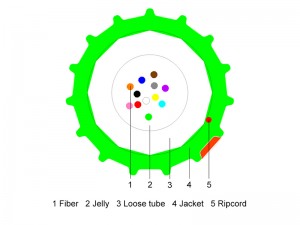

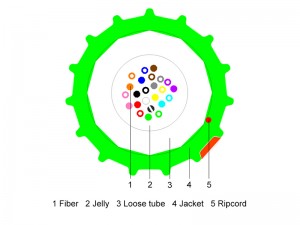

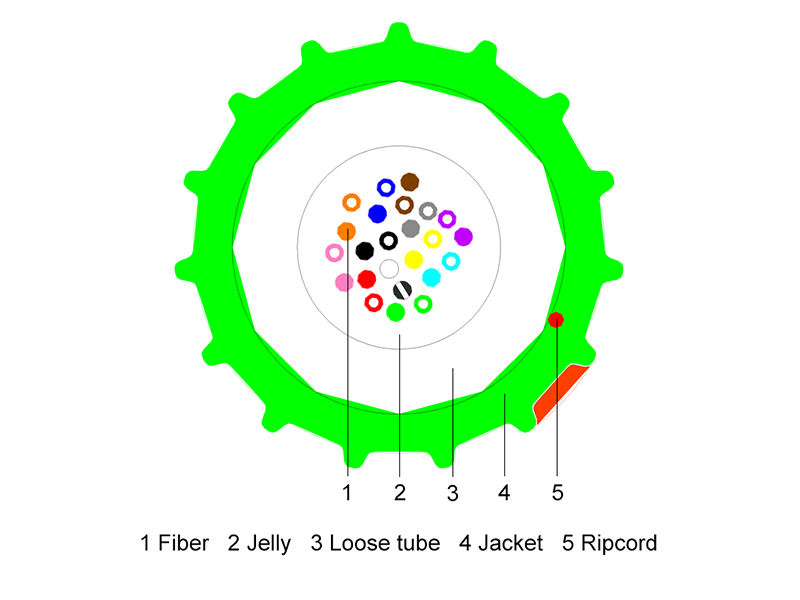

Fiber Color Identification & Sheath Color

The individual fiber shall accordance with standard TIA/EIA-598-A and the color code as below. Fiber Colors 1-12F: Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Purple, Pink, Aqua

Fiber Colors 13-24F: with black ring marks at intervals of 100mm.

Sheath color: Green or customized

Cable marking

Unless otherwise required the sheath will be use inkjet marked at intervals of 1m, containing: - Customer name

- Manufacture’s name

- Date of manufacture

- Type and number of fiber cores

- Length marking

- Other requirements

Cable Packing

Plywood drums in plywood pallets

Standard delivery lengths are 2, 4, 6 km with a tolerance of -1%~+3%.